Europe Composites Market Overview

The Europe composites market is a dynamic and rapidly evolving sector, driven by increasing demand across various industries such as automotive, aerospace, construction, and renewable energy. Composites, which combine materials with different physical and chemical properties, offer enhanced strength, lightweight characteristics, and durability, making them ideal for applications requiring high performance. In 2023, the market was valued at approximately USD 18.4 billion, and it is poised to grow significantly during the forecast period. The growth is attributed to technological advancements, the rise of electric vehicles, and the increasing focus on sustainability and energy efficiency.

Europe Composites Market Size

The Europe composites market was valued at USD 18.4 billion in 2023, reflecting the region’s strong industrial base and advanced manufacturing capabilities. The market is projected to experience steady growth, reaching an estimated value of USD 29.1 billion by 2032. This expansion is expected to be driven by increased demand in key industries, particularly automotive and aerospace, where composites play a crucial role in enhancing fuel efficiency and reducing emissions. Additionally, the rising adoption of composites in renewable energy applications, such as wind turbine blades, is contributing to the market’s robust growth trajectory.

Europe Composites Market Share

The Europe composites market is characterized by a diverse competitive landscape, with several key players holding significant market shares. The automotive and aerospace sectors are the largest consumers of composites, accounting for a substantial portion of the market. Germany, being the hub of Europe’s automotive industry, leads in terms of market share, followed by France and the United Kingdom. The market is also witnessing increased investments in research and development, aimed at enhancing composite material properties and broadening their application scope. As a result, the market share of composites is expected to expand further in the coming years.

Europe Composites Market Trends

Several trends are shaping the Europe composites market. The shift towards lightweight and fuel-efficient vehicles is driving demand for composite materials in the automotive sector. In aerospace, the need for advanced materials that can withstand extreme conditions while reducing weight is boosting the adoption of composites. Additionally, the construction industry is increasingly utilizing composites for their durability and corrosion resistance. Sustainability is another key trend, with manufacturers focusing on developing eco-friendly composites that reduce environmental impact. Furthermore, advancements in manufacturing technologies, such as automated fiber placement and additive manufacturing, are enhancing production efficiency and reducing costs.

Europe Composites Market Analysis

The Europe composites market is undergoing significant transformation, driven by the need for advanced materials that meet the evolving demands of various industries. The automotive sector, in particular, is a major growth driver, with manufacturers increasingly adopting composites to reduce vehicle weight and improve fuel efficiency. The aerospace industry is also a key contributor, leveraging the high strength-to-weight ratio of composites to enhance aircraft performance. Additionally, the construction industry is embracing composites for infrastructure projects, owing to their superior durability and resistance to harsh environmental conditions.

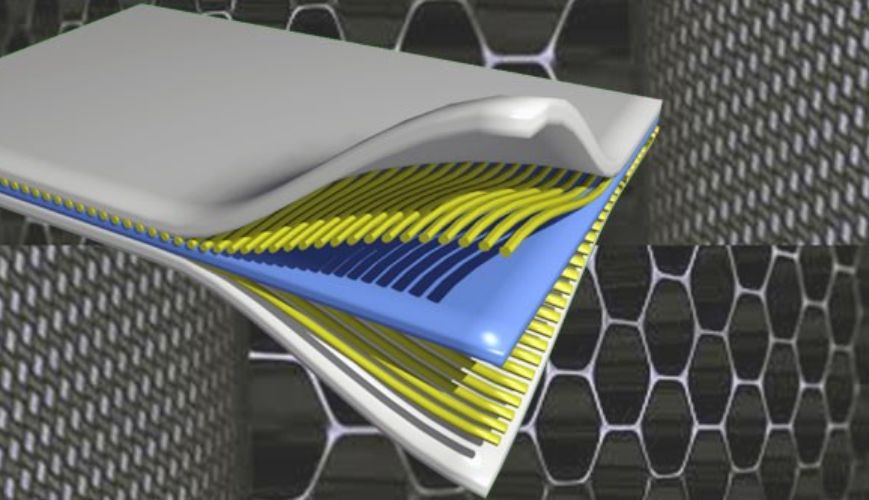

Technological advancements are playing a crucial role in market expansion. Innovations in composite manufacturing processes, such as automated fiber placement and resin transfer molding, are enhancing production efficiency and reducing costs. Moreover, the development of bio-based and recyclable composites is gaining traction, aligning with the region’s sustainability goals. However, challenges such as high raw material costs and complex manufacturing processes could hinder market growth.

Europe Composites Market Segmentation

The Europe composites market can be segmented based on the following criteria:

-

Type:

- Glass Fiber Composites: Widely used in automotive and construction sectors for their cost-effectiveness and durability.

- Carbon Fiber Composites: Preferred in aerospace and high-performance automotive applications due to their lightweight and superior strength.

- Natural Fiber Composites: Emerging as a sustainable alternative, gaining popularity in various applications.

-

Manufacturing Process:

- Lay-up Process: Commonly used in the production of large composite structures such as wind turbine blades.

- Filament Winding: Utilized for creating cylindrical and spherical composite parts.

- Injection Molding: Suitable for mass production of composite components, particularly in the automotive industry.

-

End-Use Industry:

- Automotive: The largest consumer of composites, driven by the demand for lightweight vehicles.

- Aerospace: Significant growth due to the need for high-performance materials.

- Construction: Increasing adoption for infrastructure projects.

- Renewable Energy: Growing usage in wind turbine blades and solar panel components.

Get a Free Sample Report with Table of Contents

Europe Composites Market Growth

The Europe composites market is expected to grow at a CAGR of 5.1% from 2024 to 2032, driven by increasing demand from key industries such as automotive, aerospace, and construction. The market’s growth is fueled by the rising focus on reducing carbon emissions, which has led to the adoption of lightweight and fuel-efficient materials. Additionally, the renewable energy sector is contributing to the market’s expansion, with composites being widely used in wind turbine blades. Technological advancements and the development of sustainable composites are also expected to boost market growth in the coming years.

Recent Developments and Challenges in the Europe Composites Market

The Europe composites market has witnessed several significant developments in recent years. One of the key trends is the increasing investment in research and development to enhance composite material properties, such as strength, durability, and recyclability. Companies are focusing on developing bio-based composites to meet the growing demand for sustainable materials. Additionally, advancements in manufacturing processes, such as automated fiber placement and additive manufacturing, are improving production efficiency and reducing costs.

However, the market also faces several challenges. The high cost of raw materials, particularly carbon fibers, remains a significant barrier to widespread adoption. Furthermore, the complex manufacturing processes associated with composites can lead to higher production costs and longer lead times. The market is also grappling with the issue of recyclability, as many composite materials are difficult to recycle, posing environmental concerns. Despite these challenges, the Europe composites market is expected to continue its growth trajectory, driven by increasing demand from key industries.

Key Players in the Europe Composites Market

-

SGL Carbon SE:

- A leading global manufacturer of carbon-based products, SGL Carbon SE is a key player in the Europe composites market. The company offers a wide range of composite materials, including carbon fibers, carbon-ceramic brakes, and graphite components. SGL Carbon SE focuses on innovation and sustainability, driving the development of advanced composite materials for various industries, including automotive, aerospace, and energy.

-

Hexcel Corporation:

- Hexcel Corporation is a major player in the Europe composites market, specializing in the production of carbon fibers, honeycomb materials, and other advanced composites. The company’s products are widely used in the aerospace and defense industries, as well as in the automotive and wind energy sectors. Hexcel is known for its commitment to quality and innovation, continuously developing new materials and manufacturing processes to meet the evolving needs of its customers.

-

Teijin Limited:

- Teijin Limited is a global leader in the development and production of high-performance fibers and composite materials. The company offers a broad range of composite solutions, including carbon fibers, aramid fibers, and thermoplastic composites. Teijin’s products are used in various applications, from aerospace and automotive to industrial and sporting goods. The company is focused on sustainability and is actively involved in the development of eco-friendly composites.

-

Solvay SA:

- Solvay SA is a key player in the Europe composites market, providing a wide range of composite materials and solutions. The company’s portfolio includes carbon fiber composites, thermoset and thermoplastic materials, and resin systems. Solvay’s products are widely used in the aerospace, automotive, and oil and gas industries. The company is known for its focus on innovation, with a strong emphasis on developing lightweight, high-performance materials that contribute to sustainability and energy efficiency.

-

Gurit Holding AG:

- Gurit Holding AG is a leading global supplier of composite materials and solutions. The company offers a wide range of products, including prepregs, core materials, and structural adhesives, which are used in various industries, including wind energy, marine, and automotive. Gurit is recognized for its commitment to innovation and sustainability, with a strong focus on developing environmentally friendly materials and processes.

-

FMC Composites:

- FMC Composites is a prominent player in the Europe composites market, specializing in the production of advanced composite materials for aerospace, automotive, and industrial applications. The company is known for its expertise in resin transfer molding (RTM) and vacuum-assisted resin transfer molding (VARTM) processes, which are used to produce high-quality composite components. FMC Composites is committed to delivering innovative solutions that meet the demanding requirements of its customers.

-

Others:

- Other notable players in the Europe composites market include Toray Industries, Mitsubishi Chemical Holdings, Owens Corning, and SABIC. These companies are actively involved in the development and production of composite materials for various applications, contributing to the growth and advancement of the market. They are also investing in research and development to enhance the properties of their products and expand their application scope.